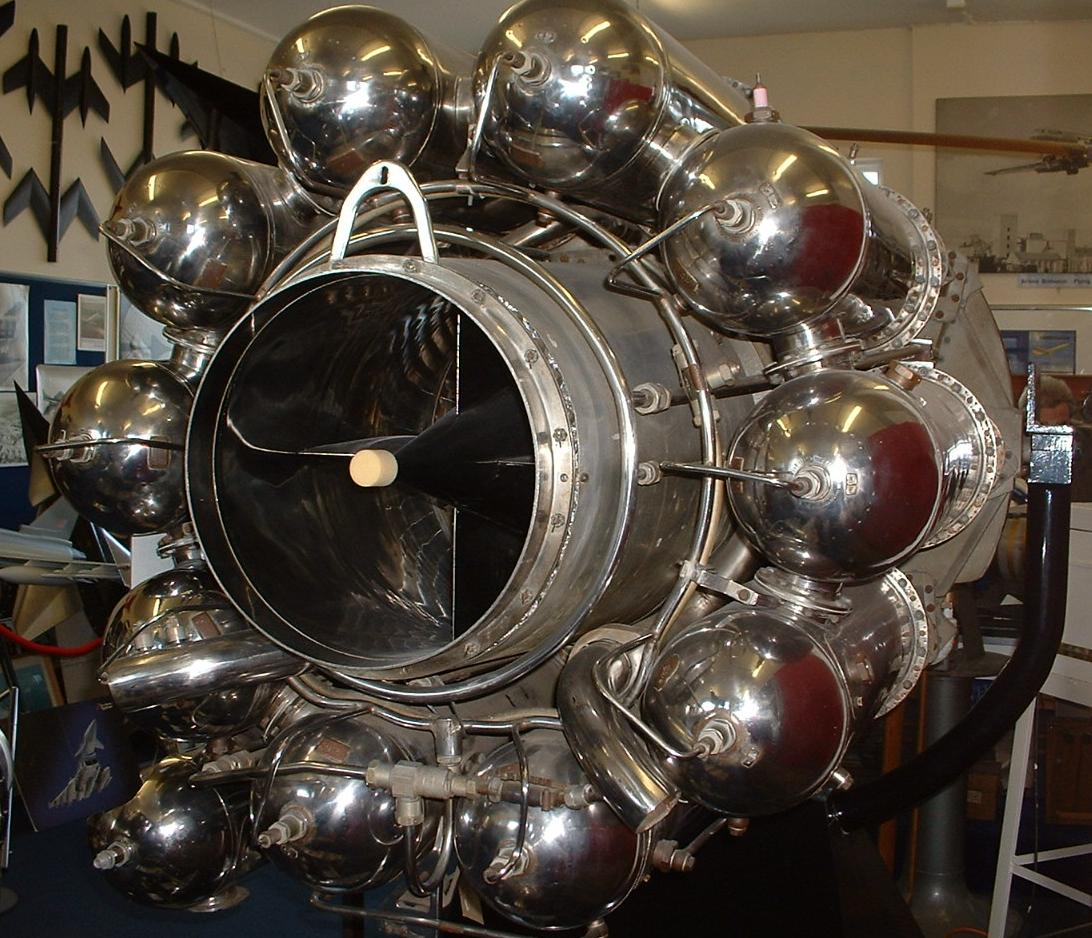

To start up a gas turbine engine, everything must work in sync with each other.

When it comes to gas turbine engines, there is a starting sequence that is vital to adequate function of the plane. Like other internal combustion engines, a gas turbine engine cannot produce any torque at zero speed. The starting mean system is used to start the turbine engine and crank it to a firing speed. This is accomplished by means of a motor, generator, or other starting device operating through a torque convert coupled to the accessory gear. Without any of these devices, there would be no turbine starting sequence – hence the plane would be stuck in a neutral position.

The Turning Gear

The turning gear provides enough power necessary to breakaway and rotate the turbine prior to the start of the turbine, and also to rotate the shafting after the turbine shuts down to avoid deformation.

Why Gas Turbine Lubrication is Important

Gas turbine lubrication is vital in the startup process. Before the actual start up and after shutdown, gas turbine lubrication is applied to ensure that there is effective lubrication of the gas turbine engine as well as to increase the performance of the turbine engine as well.

Portable Power Units

When it comes to the startup process, many planes generate electricity on their own. However, there are portable power units that can help the startup process, which are actually used at smaller airfields. These units can provide the aircraft with enough electrical current to function even without the engine being on.