How Cemented Tungsten Carbide is Benefitting Various Industries

— September 30, 2016Article written by MobaProject, mobile phone news and reviews

The benefits of cemented carbides go beyond the realm of industrialized usage.

Written by: Denton Vacuum, LLC

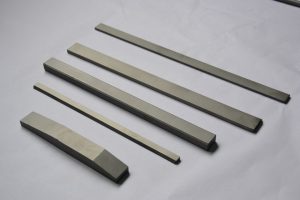

There are few materials that have affected our economy and industrialized society on a beneficial way than cemented tungsten carbide. Hard and wear-resistant, this material is utilized for items such as ballpoint pen balls, angling pole guide rings, wear parts, dental bores, shield penetrating shell centers and, most significantly, cutting devices through the process of PVD thermal evaporation – which is a commonly used deposition method in today’s market due to its beneficial factors.

Market Impact

Truth be told, cemented carbides are the most broadly utilized cutting instruments available. All things considered, they convey large amounts of profitability to the assembling procedure, which thus, brings in a hefty portion of the items utilized each day more affordable. In any case, with the variety of cutting edge covering procedures and covering materials, it’s not generally simple to decide the best embed grade for a given application.

Sputtering Systems

The best place to begin the search process is with the work piece material in light of the fact that the sort of material being machined assumes a key part in figuring out if or not a covered or uncoated carbide addition is required – as well as the sputtering systems involved.

Coated carbide inserts are an absolute necessity for working with ferrous materials, for example, iron, cast iron, steel or stainless steel. While machining super composites, it’s best to utilize a coated insert more often than not, particularly when slicing amalgams with medium to high machinability appraisals. Titanium compounds additionally advantage with coatings, particularly when not utilizing high-weight coolant within a PVD coating.