See how quality is improved through PECVD.

Plasma-enhanced chemical vapor deposition, or PECVD, is an alternative to creating thin films on a substrate. Due to the many advantages that this offers over other deposition methods, it has experienced a rise in popularity and is still an excellent option to use today.

Plasma-enhanced chemical vapor deposition, or PECVD, is an alternative to creating thin films on a substrate. Due to the many advantages that this offers over other deposition methods, it has experienced a rise in popularity and is still an excellent option to use today.

One of the many advantages of PECVD is that quality is not sacrificed when lower temperatures are used. This is important because a stable and precise result must be achieved upon completion which is something that has been an issue with deposition. CVD reactors tend to take a blow when it comes to quality upon completion. The lower temperature does not affect the film’s appearance nor does it alter it in any way whatsoever. You can achieve the result of a CVD deposit but in half of the temperature. This is one of the biggest advantages over other methods.

PECVD utilizes electrical energy to generate plasma in which it is then transferred to the gas mixture. This process transforms the mixture into a variety of highly excited ions, atoms, and molecules. Upon interaction, the substrate is then layered with the proposed material. Because the collision of the energetic species occurs in the gas phase, there isn’t a need for there to be an increase in temperature. This is the core of PECVD. Some properties that you can typically see out of this deposition method include: low pinhole density, good adhesion, and uniformity. The lack of temperature improves the overall quality of the substrate and has become a useful tool in a laboratory’s arsenal.

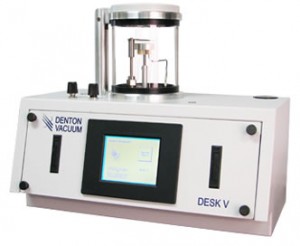

Denton Vacuum, LLC manufactures quality hardware and goods for sputter deposition. Visit them online today.